Powerdynamo brings new ignition & light

to your vintage motorcycle

|

|

Powerdynamo brings new ignition & light |

|

||||

| Some customers are worried that magnets in not plastified rotor may shake loose and create damage. | |

|

|

|

|

Older rotor 103mm diameter and all rotor 112mm and 128mm diameter show magnets visible to the eye. Those magnets are glued in with special glue. |

|

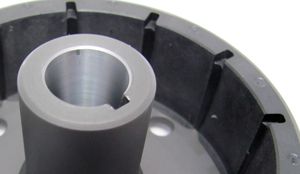

In most rotor 103mm the magnets are covered in plastics to protect them. The way how this is done varied over time. Most recent makes look as shown in the picture here. One has the impression to see individual magnets, but this is all in fact plastification, only segmented to take lateral force out. |

|

|

|

| There are reports on the web that unprotected

magnets come loose and create havoc. Indeed when a magnet gets loose, it

invariably destroys not only the rest of the magnets, but also the stator

coil. What actually might happen is that a rotor might be subjected to mechanical force which briefly flexes its steel drum. The magnets are ceramic and hence not flexible. So any flexing of the drum will shake off the inflexible magnets. Mechanical force can also be the result of brutal cooling of a heated rotor during water passages - something happening during off-road competitions (see therefore our refusal to cover this). Further, magnets get destroyed when material such as washers, small screws, pins etc enters the rotor unnoticed. Magnets love metal and pull in what they find loose. Sure that the result is havoc. There are two cases in which magnets get destroyed during engine run: - worn crank bearings - lopsided sitting base plates (due to careless assembly). |

|

Cases of magnet destruction

surely happened and each of those cases is a bad event. But those cases

are very rare and in nearly all cases the initial damage did not occur

during normal function, but as a result of having

|

|

| After whatever incident with the rotor you might have had and before installing the rotor, imperatively check magnets. As most of the magnets are indeed magnetic (some may not by design to trigger ignition) they stick to the metal drum of the rotor and you may think they are fixed. Best, whenever you handle a rotor with open magnets, try to push the magnets with your finger. A loose magnet will show up this way. | |

|

|

|

Having said all this, please

rest assured that:

|

|

|

|

|

|

One last word on magnets: For transport of our systems, please never place the stator coil inside the rotor. Especially with open magnets this may damage magnets. |

|

| back | |