Powerdynamo brings new ignition & light

to your vintage motorcycle

|

|

Powerdynamo brings new ignition & light |

|

|||

| Assembly instructions for magdyno: |

71 97 999 20 (Lucas

twin) 71 97 999 10 (Lucas single) 71 95 999 20 (Bosch twin) 71 95 999 10 (Bosch Single) |

Version 20.03.2008 |

First of all, make sure that the unit is suitable for your application. You should consider the following

points:

|

|||||||||||||||||||||||||||||||

Please note that some characteristics of the unit differ from the original

magdyno:

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

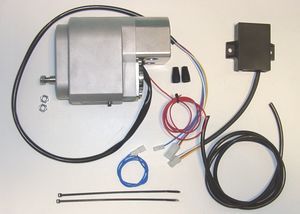

These parts are in the Lucas version pack:

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

These parts are in the Bosch version pack:

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

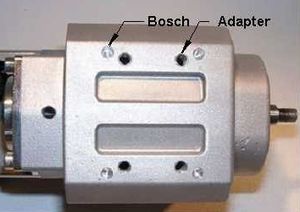

We have now unified Bosch und Lucas versions to some extent. As a result, you will find at the bottom of the unit the usual 4 holes

for the small Bosch dowels and 4 holes threaded M8 to take the

adapterplate needed for the Lucas version. Should you screw into the threaded holes for whatever reason something else than our lucas adapter plate with the screws we supply, make sure that screws do not touch the rotor inside (max screw depth from surface: 13mm) |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

For Lucas applications the unit is fitted with a bottom adapter plate, bringing the shaft to the correct height and providing for the dowels. The dowels are screwed in and may therefore be taken out (hex key) or replaced by screws (watch out for length!) if required for the particular installation. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Not included, but necessary if you operate without a battery, is a smoothing

capacitor. It must be installed in place of the battery and connected as if it

were the

battery. The capacitor has 2 screw-on terminals. One of them is marked with plus (+) and must be connected to plus (+). The other terminal (-) is connected to ground (negative). The red positive (+) wire of the magdyno must be connected to both the positive (+) terminal of the capacitor and to input terminal (pin 30) of the main switch, if fitted. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Recommended, for operating without a battery, but not included

in the magdyno set is an

* empty battery housing (similar in appearance to original Bosch) to contain both advance unit and capacitor. |

||||||||||||||||||||||||||||||

|

This empty housing may also be used to house a modern 12V sealed acid battery while maintaining the appearance of the original. | ||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Preparation of Installation |

|||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

| The new magdyno is fastened to the motorcycle in the same way as the original magdyno had been fitted. | |||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

This adjustment of mesh is usually effected by placing shims between the unit and mounting platform. A worn idler may exhibit the same slow speed clatter even though the mesh is correct. For more detail on that see safety and operating information further down. |

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

| Observe that the taper of the rotor shaft is 1:5 and threaded for M8x1. Do not use sprockets on it with a different taper. This will damage the taper and may cause the sprocket to slip on the shaft. | |||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

During assembly, pay attention to the small switches on the advance unit. There are 2 blue switches which select different advance curves. | ||||||||||||||||||||||||||||||

| For settings and curves of units

with serial numbers starting with 0806 and 1506

see here.

Other (later units have settings as described below). |

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

In the table below 1 means switch is set to ON 0 means it is set opposite, that is to OFF this example here is 1-0 |

||||||||||||||||||||||||||||||

Those curves have been introduced as it had been noticed that some machines with worn yet serviceable engines had difficulty in maintaining a regular idle speed of 1,000rpm or below. It was therefore necessary to introduce an A&R module with the advance threshold lifted to 1,250rpm to allow idle speeds to be increased to 1,250 rpm or below. At the same time it was advantageous to modify all settings to give a greater spread of options. |

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

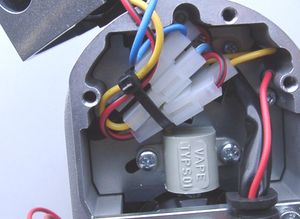

| The magdyno and its external advance unit are connected by a pre-assembled 4-terminal plug. | |||||||||||||||||||||||||||||||

|

If you have to replace it or there are cables out of the

plug, you must take care that all cables are connected correctly (see

left).

If the blue cable is connected to ground, the ignition is off. For a first test of the system you are advised to leave the blue wire open (unconnected). This will reduce the scope of possible errors. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

For ignition adjustment you must: |

|||||||||||||||||||||||||||||||

|

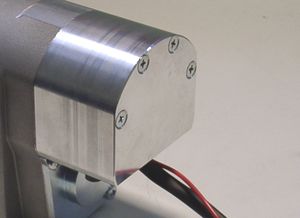

Remove the 4 countersunk screws from the front upper cover. (Not the 4 lower hex head screws!) | ||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

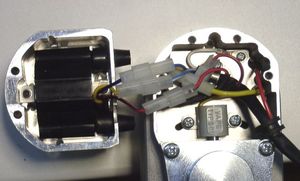

Pull off the cover (cap) carefully.

Attention, not too far! The ignition coil is fastened with cables and plugs connected to the inside of the unit. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

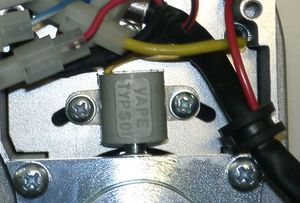

You will see the grey sensor, and beneath it the rotor with its 2 trigger

noses.

The point of ignition is determined by the position of the trigger noses relative to the sensor. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

To facilitate turning the shaft, there is a hex screw in the end of the rotor shaft with an accessible

head.

You may insert a 3mm allen key to turn and hold it. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Setting timing during

installation

This is the point where most problems happen, so please read carefully and try to understand the logic of the process. |

|||||||||||||||||||||||||||||||

| 1. Prepare the new unit by setting it into position for full advance. | |||||||||||||||||||||||||||||||

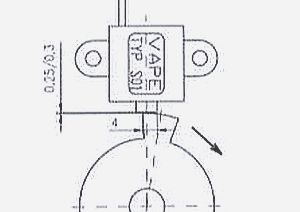

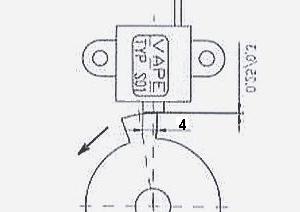

| The following drawing shows where the sensor and rotor are in relation to each other when the spark actually occurs under conditions of maximal advance (that is normal driving speed). | |||||||||||||||||||||||||||||||

|

Position at full advance

The position of full advance is reached (for clockwise turning units) when the left edge of the trigger has passed the sensor core by about 1/3 of its width (4mm). Turning clockwise means as seen from the front of the shaft (as shown here)! |

||||||||||||||||||||||||||||||

|

For counter-clockwise turning units (seen from this position) the same applies in

reverse.

The system is designed to work in either direction. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

| 2. Prepare your engine by setting the crankshaft into the position that is normally reached at full advance (riding position). For most motorcycles using a magdyno this is typically around 38° to 40° (crankshaft) before TDC single spark advance and 32° to 34° twin spark. | |||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

| 3. With both, unit and engine in the described position the mag pinion or cog should be gently tapped onto taper and secured to 14 ft lbs with nut provided. Re-check timing in case of slippage. | |||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

A perfectly accurate adjustment may be difficult (often prevented by the length of the timing chain links).

Furthermore, positioning the rotor precisely in specified positions can be tricky as well

(because of the strong magnets pulling it away).

We have therefore provided a means to adjust the sensor position by shifting it laterally. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

But attention: Loosen the holding screws only slightly - otherwise the back plate behind may fall inside the unit (attracted by the magnets) and damage the system, if you start it. Don't forget to tighten the screws after the adjustment!! Please check these screws for tightness even if you did not adjust the sensor position initially. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Whenever you have opened the ignition coil housing, you must be careful to ensure that all wires there are well secured and can not accidentally become entangled in the

rotor. Use a cable tie to fasten them well up.

Attention: Before starting fit a new plug and open the gap to 0.6mm/25thou. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

There is no reason to open the unit (except the cover for adjusting the sensor and checking screws and

cables)!! There are no other serviceable components inside. Unscrewing the rotor mounting plate could lead to severe damage and will void the warranty. If you suspect a defect in the system, you must return it to Powerdynamo for inspection and (if needed) repair. If you must know how it looks inside - here is a photo! (Click pictures to enlarge them!) |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

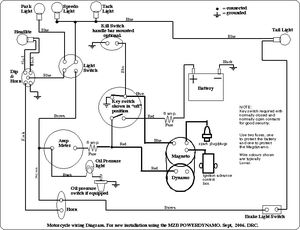

| Wiring will depend very much on what motorcycle you are using the magdyno for. There are however a few generally valid points. Below a general wiring diagram of a typical (British) vintage motorcycle with the new unit. You may enlarge this diagram by clicking onto it. | |||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

The single cylinder version differs from the twin cylinder

(or twin spark) version only by the ignition coil and its cover.

Both have the same rotor with 2 noses and hence produce a wasted (harmless) spark on the exhaust stroke. If there is a twin ignition coil fitted, it always fires both plugs at the same time. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

| During operation the unit will warm up

noticeably, especially at the front and the bottom. This temperature may

(with motorcycle not moving) climb up to 85°C (you should be careful when touching the hot

unit). This heat will not damage the electronics and is actually not produced by the electronics or near them. The heat comes from the

aluminium. Similar to a microwave oven, the strong magnetic field causes the alloy particles to rub against each

other, heating themselves up.

This is normal behaviour of the unit, there is no need to worry. |

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

| You will not be able to turn the shaft by hand. You must place a sprocket on the shaft

(or use the allen key in the front opening). When turning the shaft you will notice the resistance of the

magnets. That too is normal. Energy does not come from nothing. The high output of the unit requires a strong magnetic field created by very powerful high technology ceramic magnets.

Having mentioned the internal resistance, there is no need for worry that your engine cannot pull it, or will suffer a loss of power. Quite the contrary, you should notice improved engine performance. You may ease starting by switching the lights on only after the engine is running on its own. The lights consume a lot of energy and bring more load to bear on the magnets. That is a suggestion only, if needed. The engine will start with lights switched on before starting as well. |

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

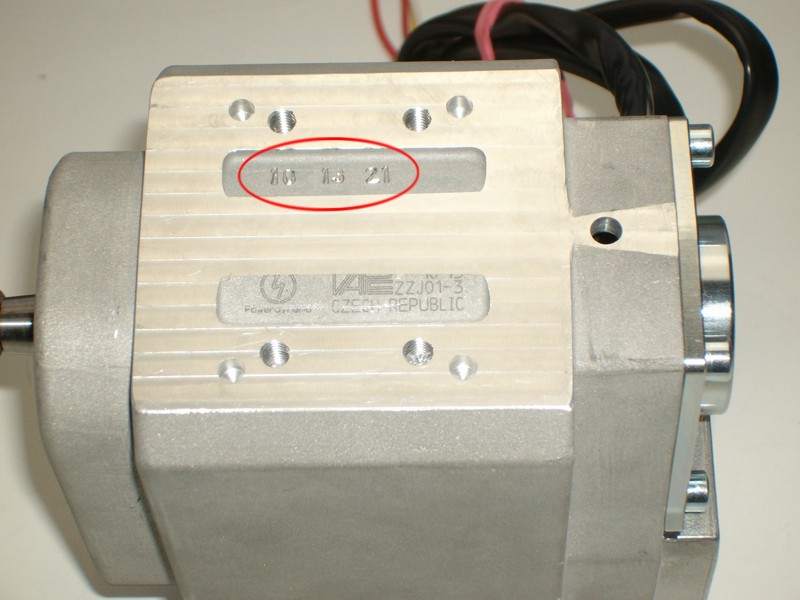

You will find a unique unit idendity number on the bottom right-hand side. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

You may check timing with a stroboscope. For this the engine has to be

running however.

Precise ways of doing that vary from motorcycle to motorcycle. You cannot check timing with a simple timing light bulb as used in points based applications. |

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||