Powerdynamo brings new ignition & light

to your vintage motorcycle

|

|

Powerdynamo brings new ignition & light |

|

|||

|

|

||

|

||

|

|

||

| RD where the rotor is bolted to the

crank by screw M7 (with originally points |

RD where the rotor is

bolted to the crank by nut (with originally CDI ignition |

|

| 1976 RD250C & RD400C 1977 RD250D & RD400D The rotor on these models is retained with a 7mm bolt | From 1978 all RD250/400ís (with CDI ignition) had the rotor retained with a nut, these models are commonly known as 1978 RD250E & RD400E 1979 RD250F & RD400F as well as (for Germany) G models. All these models have CDI ignition systems and the flywheel is retained by a nut | |

| Please note: in some RD 400 (sorry we do not know which 400 models are concerned) with stock points we got several times problems with the dynamo cover after our system 71 05 799 was fitted. | ||

|

|

|

|

|

|

|

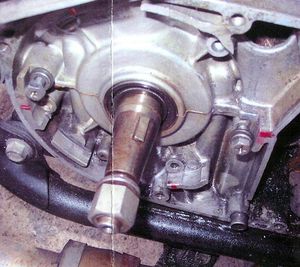

| With this type of shaft there is no uncertanty as to which of our systems will fit | ||

| Our systems fitting those engines are | shorter shaft | longer shaft |

|

For more see below |

||

| Our systems fitting those engines are | Our systems fitting those engines are | |

| distinction between the two is not easy and needs close scrutiny of the shaft. | ||

| Distinction between the 2 different shaft types with threaded shaft end | ||||

| shorter shaft with nut | longer shaft with nut | |||

|

|

|

|||

| The length of the shaft from bottom level of base plate

(engine support) to end of taper (start of threading) is ca 42mm.

|

The length of the shaft from bottom level of base plate

(engine support) to end of taper (start of threading) is ca 51mm.

|

|||

|

||||