Troubleshooting on PD Magdynos

|

|

|

Our Magdynos are of rather sturdy construction and are well tested. Still,

they represent a complex technical system which might fool the customer

into thinking it is not working correctly or which might indeed be

malfunctioning. Here some guidelines of what and how to check. Please also consider that not the magdyno, but something else in your bike

might be the reason for the problems you experience. See

more information here

We have found that in certain sports machines with very high

compression, e.g. BMW R63, R16, R17) there is a problem with starting.

Once running, the engines run flawlessly, but starting might be difficult

(not enough starting revolutions). In all other applications so far the

problem has not been observed.

|

|

Here an overview of the most frequent problems:

- Bad or wrong spark plug caps and/or spark plugs creating too much

resistance.

(more info see here)

One customer who at start had difficult starting reportet: I have

fitted new plugs, NGK B5HS; so far so good. I have ridden from

Milan to Taranto and back, 2,900 km and everything is working fine.

Normally B6HS would be recommended. I hope I have solved the problem!

- Bad ground! In case of doubt, connect a special ground wire

from the engine block to one of the 4 rear screws holding the zinc

plated lower rear cover.

- Testing with rear cap

(housing ignition coil) off. To test with this cap off, you

imperatively need to apply ground to this cap. Otherwise there will be

no spark.

- Damaged wires (connecting ignition coil to inner of the unit) as a

result of bad assembly. Either wires got into the way of the trigger

noses of the rotor shaft or are damaged by the screws holding the rear

coil cover.

- Over-wide gap between trigger protrusion and sensor. This has to be

maximal 0.4, better 0.3mm.

- Dirt, water and (worst of all) alien metal particles inside the unit

- the strong magnets tent to collect everything!

- Wrongly connected wires between ignition coil and inner unit (see

below for correct position).

|

|

|

It might well be that the unit is ok, but you get fooled by your testing

procedure. For this please know:

|

- You need to test the magdyno in kickstart-reality. We mean to say

that the engine has to be started by good kicks in order to produce

sparks. Mere turning at the rear wheel would not produce enough

revolutions. Needed are shaft revolutions of above 110 revs (that is

220 crankshaft). Below you get no spark.

- The spark is extremely focused and hence difficult to see. See

info here

- With twin coils, you can not test with one plug open. See

here.

|

|

|

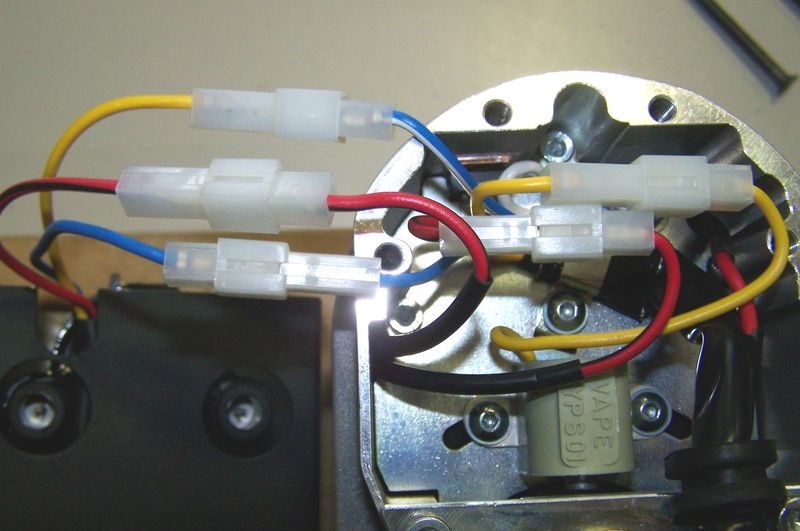

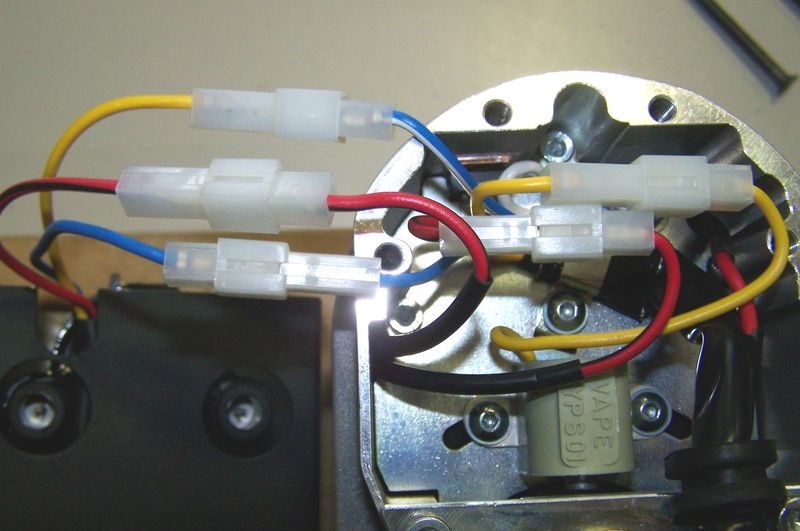

Here is how the wires to the ignition coil should be connected:

- yellow from coil to blue/white from unit

- red/black from coil to red/black from unit

- blue from coil to blue from unit

- inside the unit connect yellow to yellow and red/black to red/black

Check

especially after having disconnected the coil.

|

|

|

Note: The following is for the experienced

customer only.

Wrong action and especially any application of voltage to the unit from

outside would harm the unit. Take also great care not to allow alien

material to enter the unit. Its very strong magnetic field will easily

collect small screws, washers and the like, leading subsequently during

run to destruction. Equally refrain from taking the shaft out.

|

|

You can not check everything, but some resistance values can be

checked with an Ohmmeter. For this you need NOT open the unit, just

disconnect the advance module

NEVER EVER apply any voltage to the unit from outside !

|

- first thing to check is ground. check resistance between the

magdyno body and the white wire in the cable bundle that runs to the (now

disconnected) advance module. You should not have any resistance here.

If you have, there is some internal bad ground contact.

- you may check the charging winding

inside unit (not HT coil) by checking resistance between the red/black and

white (ground). This should be about

865 Ohms. This value might vary in hot (working temperature) or moist conditions

|

- you can check the pickup (sensor) by checking resistance between the

yellow and the white wires. This should be 200 Ohms. When you turn the

shaft so that a trigger nose inside of it passes the sensor you get a

quick change of that reading. You can not see what it changes to as it

is so fast, but you can see a sudden change - indicating impulse has

been given.

|

- you can check input resistance of the ignition coil by checking resistance between

blue/white and white. This should have 120

Ohms.

|

- you can check the secondary (HT side) winding of HT coil. Here

check resistance between the 2 HT outlets. This should have

6,6 kOhms.

At this point use the occation to place both spark plugs into the caps

and check resistance from tip to tip (see here).

This should not have more than 10 Kiloohms

|

- finally you can check input resistance of the advance unit. Here

resistance between yellow and white of the advance unit (not the wire

into the magdyno) should have 1 kOhm.

|

- and you can indirectly check whether the advance unit is faulty by

bypassing it for a test. With this test the engine will not run, as

timing will be grossly out o normal, but the advance is eleminated as

a possible source of malfunction and you might see (if everything else

is ok) spark.

For this, bridge the yellow and the blue/white wires running from the

magdyno and kickstart without the advance. If you get sparks that way,

but not with the advance unit connected than chances are that the unit

is defective.

|

|

|

|

|

back to Knowledge base

|