Powerdynamo brings new ignition & light

to your vintage motorcycle

|

|

Powerdynamo brings new ignition & light |

|

|||

| My (2 stroke) motorcycle had a centrifugal govenor for advance control. The new Powerdynamo system now says it has fixed timing. How should this work on my bike? | |

|

|

|

|

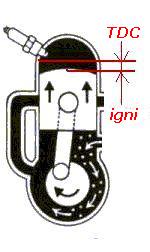

Till about the mid 60s most 2 stroke engines had a

centrifugal govenor that controlled ignition timing. It permitted those

engines to start near TDC (top dead center) and as soon as the engine run,

changed to driving position of about 28 degrees BTDC (before top dead

center This was mainly needed because of the bad carburants at the time, having a mere 60-70 octan (before the war even as low as 40 octan). Starting with full normal advance was extremely difficult with those carburants. Sa a centrifugal govenor was used to help starting. With carburants getting much better in the 70s, this expensive and difficult to maintain part was supressed. You will not find it any more on later 2 strokes (sure you find it on 4 strokes!). |

|

|

|

TDC - the highest point a piston can reach the normal moment of ignition is always a few millimeters before this.

therefore called BTDC (before top dead center). |

With the modern carburants (which now well into the 90s are actually to hot for those old motorcycles, but you have no choice but to use it) the need to change timing during starting is no longer there. Even less so with the high power condenser discharge ignition (CDI) as you have with Powerdynamo. You even should get a situation where the old factory value for normal

ignition might no longer be valid. Flame development is so rapid that you

need to set ignition nearer to TDC than your old manual might indicate.

This we experience in most motorcycles made before about 1970 and now

equipped with Powerdynamo. |

|

|

|

|

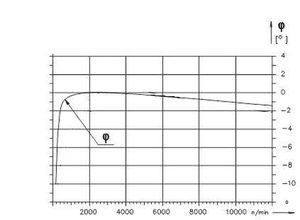

There is however some sort of advance/retard inherent in the material. The diagrams here shows timing of spark in depencence of engine speed in our internal sensor systems

|

|

|

| back to KB overview |