Powerdynamo brings new ignition & light

to your vintage motorcycle

|

|

Powerdynamo brings new ignition & light |

|

|||

| Assembly instructions for systems 70

67 999 4K and 71 67

999 4K the difference between the two is the diameter of the base plate only |

Version 27.10.2014 |

|

If you can install and time a stock ignition and

possess basic mechanical skills, you can install a Powerdynamo! |

|

| Powerdynamo can not monitor the compliance to those instructions, nor the conditions and methods of installation, operation, usage and maintenance of the system. Improper installation may result in damage to property and possibly even bodily injury. Therefore we assume no responsibility for loss, damage or cost which result from, or are in any way related to, incorrect installation, improper operation, or incorrect use and maintenance. We reserve the right to make changes to the product, technical data or assembly and operating instructions without prior notice. | |

|

|

Please read these

instructions fully and carefully before starting work on your motorcycle Please bear in mind that any modification of the material as well as own repair attempts which have not been agreed with Powerdynamo may result in a loss of warranty. Do not cut off wires. This leads to a loss of reverse polarity protection and often results in damage to electronics. Also, please take note of the information provided on the information page for this system. Check that what you have bought really corresponds to the motorcycle you have. Wrong ignition settings may damage your engine and even hurt you during kickstart (violent kickbacks). Be careful during the first test runs. If needed change settings to safer values (less advance). During assembly check carefully that the rotor (flywheel) does not touch the stator coils or anything else, which may happen due to various circumstances and lead to severe damage. |

| Designated use This system is designated to replace stock dynamo/alternator & ignition systems in vintage and classic motorcycles whose engine characteristics have not been modified aftermarket. This system is not a tuning system and it will not bring significant increases in engine output. It does however significantly enhance roadworthiness and comfort by offering better lighting, better function of side indicators and horn and, compared with the aging stock systems, increased reliability. As our system does not tamper with engine characteristics it does not increase emission of gaseous pollutants and noise. In most cases emission of pollutants should even be reduced due to better combustion. If used as designated the system therefore will not normally infringe the existing legal status of the motorcycle (this statement is valid for Germany, for other countries, please check locally against your road licensing regulations). This system is not suitable for use in competition events. If used other than the designated way, warranty will be voided and it might well be that you do not obtain the desired results or, worst you loose legal roadworthiness. The charging system is only suitable for use with rechargable 12V (6V systems 6V) lead-acid batteries with liquide electrolyte or sealed lead-acid batteries, AGM, Gel. It is not suitable for use with nickel-cadmium, nickel-metal-hydride, lithium-ion or any other types of recharchable or non rechargable batteries. This is a replacement system and not a copy of the stock material. The parts in this system therefore look different and might fit differently (notably ignition coil and regulator) requiring some adaptation by you. |

|

| During assembly imperatively start with assy of engine based parts to see that those really fit before you start fitting the external parts. In many cases customers assemble those first and thereby often modify them in breach of warranty which renders them unfit for renewed sale. Replacing old ignition systems is not a matter of taking something from a supermarket shelf as there have been very many types, versions and possibly unknown aftermarket modifications which harbour plenty of room for error. | |

| Our systems are NOT tested for use with third party electronic devices (such as GPS, mobile phones, LED lighting etc)and may cause damage to such parts. Possibly existing electronic tachometers will not work with the new system. Read our information for suitable solutions. Possibly existing safety switches and electronic valve controls are not supported. It might be that your motorcycle was originally equipped with an ignition that did limit top speed for legal reasons. The new system does not have such a facility, so check your legal situation beforehand. | |

| If you have no expertise for the installation have it done by an expert or at a specialist's workshop. Improper installation may damage the new system and your motorcycle, possibly even lead to bodily harm. | |

| Before you order a system, please check whether a puller

tool for the new rotor is included in the kit. If not,

better order it at the same time. You might want to order light bulbs,

fuse, horn,

flasher

unit etc. Never use anything other than the recommended puller tool to pull the new rotor again. Damage to the rotor as a result of use of other tools or methods is not covered by warranty. |

|

| The rotor is sensible to blows (including during transport). Before assembly, please always check for damage (on rotor without magnet plastification try to push the magnets aside with your fingers). After impact the glued in magnets might have broken loose, sticking to the rotor solely by magnetic force, so that one does not notice right away. During engine run the damage would be considerable. Before placing the rotor onto the engine, please make sure that its magnets have not collected any metal objects such as small screws, nuts and washers. That equally would lead to severe damage. | |

| If you have access to the Internet, best view those instructions online. You get larger and better pictures by clicking onto them and possibly updated information. System list at http://www.powerdynamo.biz | |

|

You should have received those parts:

Please note that the sensor (pickup) is only loosely fixed, as you will have to set it to correct gap. Fasten it well after adjustment. |

|

To disengage your new rotor again, you will need a

puller M27x1.25 (part-no.: 99 99 799 00 -Not provided!-).

Note: Never use a claw puller, a hammer or any other device, that will shake the magnets off. |

|

|

|

| Make sure your motorcycle rests securely, preferably on an elevated work bench and that you have good access

to the front of the engine. You will have to turn the front wheel

from time to time for better access.

Disconnect your battery and take it out of the motorcycle for the time of work. |

|

|

|

|

|

Disconnect all cables at the alternator, condenser, points (or hall element), ignition coils, the diode plate and the regulator unit and remove those parts. |

|

|

|

|

As the fixing point of the stock ignition will not be used furthermore, you may remove the parts there, but than make sure the area is oil proof. |

|

|

|

|

Put the pre-assembled stator plate instead of the original alternator onto

the engine case. The sensor (pick-up) will show into some half past one direction. Screw this plate down with the supplied 3 screws M5. Place the screws in the center of the oblong holes for possibly later adjusting the ignition. Lead the cable upwards through the opening in the rear part of the engine casing. |

|

|

|

Have a look at the new rotor. You will find on the circumference some long protrusion. This is to trigger ignition. However it does not do so when this elevation reaches the sensor, but after it has gone past it as the system needs to calculate the advance based on engine speed (the time the protrusion needs for one passage used as reference).

In this picture here the rotor is in TDC position. |

|

|

|

|

|

In this picture here the rotor is in ignition at maximal advance position. The picture indicates the precise position of rotor versus sensor at

maximal advance (the FZ mark). |

|

|

|

|

Take the spark plugs out. Place the rotor onto the crank shaft (without screwing it down there) for using it as a turning knob. Bring the crank shaft into FZ position (maximal advance) by using the spyhole. Pull off the rotor again (you will possibly need the a M27x1.25 puller for this) without changing the crank shaft position. Than place it back onto the shaft in such a way, that the protrusion aligns to the sensor as shown above. |

| Now fasten the rotor with the supplied screw (and washer). Make sure not to change the crank's position during this. Minor deviations of 1-2mm are harmless (the original centrifugal governor had the same tolerances). | |

|

|

|

|

Now, again turn the rotor by hand and check the gap between the sensor and the rotor's elevation. It has to be 0.4 mm. Adjust it by loosening the sensor's mounting screws and shifting the sensor a little. Do not forget to fasten the screws well after that. Finally check that the rotor runs freely above the

stator plate. |

|

|

|

|

You could position the parts at every other convenient place. |

|

|

|

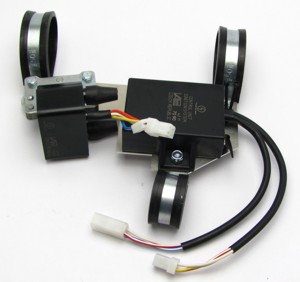

| Have a look at the small blue switch block at the upper (wire exit) side of the "Black Box" (advance unit). There are 4 little switches for choosing different advance curves. | |

|

recommended curve with switches 1,4 ON, 3,4 OFF you have advance change from 24° to 39°. This setting has been found best by customers running this system by now more than 50.000 miles |

|

all switches to OFF (against ON). This will bring advance of 9° BTDC at start and 38° at 3.000rpm. |

|

|

|

|

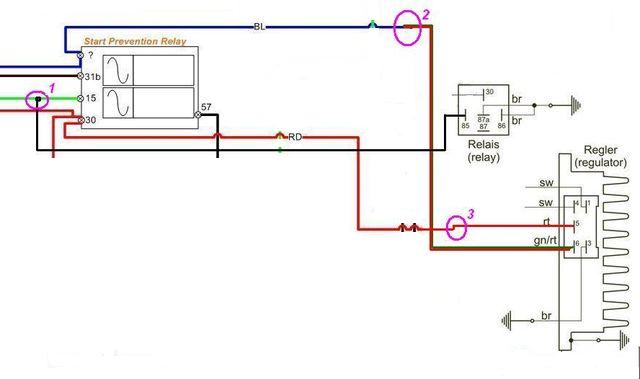

The new system will be wired between the new parts as explained below. If your BMW had (in /5 and early /6 only we think) a relay to prevent starting into already running engine (Anlasswiederholsperre) you need to implement the following changes. If there is no such relay (which please do not confuse with the new cut off relay the Powerdynamo system brings in) please skipp the following. There are 3 connections to modify

With his arrangement, both the BMW charge control light and the starter prevention relay will function as before. |

|

|

|

| For a stock wiring diagram see here (note there have been different versions of this) | |

|

|

|

|

Connect the parts as shown in wiring diagram 94xk12: |

||||

| * |

|

Look for the stator unit with its male plug and the three wires (red,

white and yellow). Connect it with the fitting (female) plug of the

advance unit (also with the wire colors red, white and yellow).

Check that here always connected the same colors together:

|

||

|

|

|

The plug of one ignition coil will be connected to the still open plug of the control

unit. This two

plugs can only be connected in one position. Note the changing colour:

|

||

|

|

|

The plug of the second ignition coil will be connected to the still open plug of the

stator unit. This two

plugs can only be connected in one position also. Note here the changing

colour also:

|

||

|

Should you need (or want) to get the terminals out of the plug housing again, enter a paper clip from front next to the terminals and push the little barb aside. Than pull the wire out. |

||||

| * |

Important! Never run the high tension cable(s) and the cable(s) of the advance unit closely in parallel (say in one shielding). This will trigger back coupling that disturbes ignition and might even damage the advance unit. |

|||

| * | Connecting Powerdynamo alternator to lighting circuit (via regulator): | |||

|

The 2 black wires running from the stator

coil carry the voltage for lights, horn, flashers etc. They have nothing

to do with ignition. This voltage (something between 10 and 50 volts AC) has however to be stabilized (regulated) and for most uses rectified into direct current (DC) as it primarily is alternating current (AC). |

|||

|

|

||||

|

* |

|

The new regulator/rectifier has a compact plug with 6 positions, of which one is not used. A female plug cover fitting to this plug is delivered. Into this female plug you have to insert the following wires (which have terminals that snap into the plug): | ||

| The two black cables leading from the generator ... |

... connect to pins 1/4 of the new regulator (from there correspondingly black wires lead inside the unit). It does not matter which wire connects to which of the both terminals (1/4) as they carry alternating current. |

|||

| The new brown cable with the round eye terminal ... |

... connects pin 3 of the regulator unit (from there correspondingly a brown wire goes inside the unit) with the negative terminal on the battery or (in case you drive without battery) to ground/earth (chassis). |

|||

|

The new red cable with the round eye terminal ... Take care: |

... connects to pin 5 of the new regulator (from there correspondingly a red wire goes inside the unit). Here your regulated positive voltage comes out to connect to positive terminal of the battery, or (in case you drive without battery) to the positive pin of the main switch (ignition lock, German bikes: pin 51/30). |

|||

| Make sure that you have a 16A-fuse between battery and vehicle circuitry. | ||||

|

The green/red wire at pin 6 of the new regulator ... Remark: |

... is for the charging light.

You connect there the wire that formerly did run from the control light to

the original regulator. |

|||

| The charge light control function is based on a transistor switch and is an additional function. Even if that should fail, the regulator might still be in ok working condition. Simple check: have the engine running, turn lights on, disconnect the battery. If you have bright lights the unit is ok. | ||||

| * |

Remain the blue (sometimes blue/white) wires at the ignition coils. These are the kill (cut-out) wires.

Note: |

Connected to ground - it

will stop ignition!

This type of wiring is used in motorcycles which originally already had magneto ignition and therefore switched off by shortcircuiting against ground. Those vehicles have by design a main lock (or some kill switch) that connects a pin to ground when in OFF position (German bikes: pin 2). The blue(/white) wires of the ignition coils will be connected here. In that way the cut-out works like previously. |

||

| * |

Screw the high tension (ignition) cables ...

Please do not use any spark amplifying cables, such as "Nology supercables" or "hot wire". This will disturb the system and possibly damage it. |

... into the ignition coil and pull over the rubber seals before

mounting the

coil (it will be easier).

Please do use the cable arriving with the pack and not any old cable. |

||

|

You will be doing yourself a favour to treat your bike to new spark plugs and

spark plug caps (preferably some between 0-2kOhm).

Plenty of problems are to be traced back to "apparently good" (even

completely "brand-new") sparks plugs, terminals and cables. Do not use spark plugs with an intern suppression resistor. NGK (e.g.) offered such spark plugs coded with an "R" (for resistor). |

||||

| * |

|

In our twin outlet coils both ends of the secondary go to the spark plugs.

Typical resistance between both exits is 6.2kOhm. Both exists fire at the same time (as many twin systems do). Sparks will be polarised however at a 180 degrees difference which might manifest when you strobe it. |

||

|

Ignition will only work correctly if both plug terminals are connected.

You may not test one side with the other open (not sitting on the mounted

spark plug). This is because (effectively) each exit uses ground from the

other. That means also that both plugs are working in serial, adding

resistances, so better use low resistance spark plug (resistor) sockets

and make sure they are good. If in doubt, measure resistance on a hot

socket (warm it up before measuring).

Is the flow from ground of one side via spark plug there, via coil, to the other spark plug and its ground interrupted you get no spark - on neither side. If you really want to test only one side, put the HT wire of the other to ground (earth it) than it will work. Sometimes a coil deprived of its ground from the other side searches for a substitute - with some solid fireworks around it to the chassis. |

||||

|

* |

Finally - and before installing the battery and before the first attempt to kickstart - please re-check carefully all connections and fitments with the wiring diagram. Do check battery and light bulbs for correct voltage (12V). Should something not work, please consult our trouble-shooting guide on our homepage. As a first step disconnect the blue wire from the coil and re-test. |

|||

| * |

IMPORTANT: During crank shaft repair the dynamo shaft is often

machined and gets shorter. The result is a rotor sitting lower, possibly

touching now with its rivets the stator coil. The result is a destroyed

stator and ignition failure. For more detail and how to check see (online) here. |

|||

|

|

Important safety and operating information |

|

# |

Safety first! Please observe the general

health and safety regulations motor vehicle repair (MVR)

as well as the safety information and obligations indicated by the

manufacturer of your motorcycle. The timing marks on the material are for general guidance only during first installation. Please check after assembly by suitable means (stroboscope) that settings are correct to prevent damage to the engine or possibly even your health. You alone are responsible for the installation and the correctness of settings. |

|

# |

Ignition systems generate high tension! With our

material right up to 40,000 Volts! This may, if handled carelessly, not

only be painful, but outrightly dangerous.

Please do keep a safe distance to the electrode of your spark plug and

open high tension cables. Should you need to test spark firing, hold the

spark plug socket securely with some well insulating material and push

it firmly to solid ground of the engine block. Never pull sparkplug caps when engine is running. Wash your vehicle only with engine at standstill and ignition off. |

|

# |

Should you have received in the kit HT cables with a fixed rubber boot(which does not contain a resistor) you might have to use spark plugs with an inbuilt resistor (or replace the cap with one containing a resistor) to comply with your local laws. |

|

# |

After installation, please check tightness of all screws, even those preinstalled. If parts get loose during run, there will be inevitably damage to the material. We pre-assemble screws only loosely. |

|

# |

Give the newly installed system a chance to work, before you start

to check and test values, or what is worse apply changes to it. Our parts have been checked before delivery to you. You will not be able to check much anyway. At any rate do refrain from measuring the electronic components (such as ignition coil, regulator and advance unit). You risk severe damage to the inner electronics there. You will not get any tangible results from the operation anyway. Bear in mind that also your carburetor, your spark plugs and spark plug sockets (even if completely new) might be the reason for malfunction. The general experience with our systems is that the carburetor will have to be re-adjusted to lower settings. Should the system not start after assembly, first disconnect the blue (or blue/white) cut-off wire directly at the ignition coil (or in some cases advance unit) to eliminate any malfunction in the cut-off circuitry. Check ground connections carefully, make sure there is a good electrical connection between frame and engine block. In case of troubles, please consult our Knowledge Base first before you send off the material to us for checking |

|

# |

The spark of classic, points based ignition systems has with about 10,000 Volts comparatively little energy and looks therefore yellow and fat (which however makes it highly visible). The spark from our system is a high energy spark with up to 40,000 Volts and therefore is needle thin focused in form, and blue in colour, which makes it not so visible. Furthermore you get spark only at kick-start operated speeds and not by pushing the kick-lever down slowly with your hand (as you might get with battery based ignitions). |

|

# |

Systems using a twin outlet ignition coils have a few peculiarities. Please observe that during tests on one side, the other has either to be connected to an fitted spark plug or securely earthed/grounded. Otherwise there will be no spark on either side. Also with such open exits long and dangerous sparks may fly all over the coil. |

|

# |

Never do electric arc welding on the bike without completely disconnecting all parts containing semiconductors (ignition coil, regulator, advance) stator and rotor need not be taken off. The same is true for soldering. Before touching electronics disconnect the soldering iron from mains! Never use copper putty on spark plugs. |

|

# |

Electronics are very sensitive to wrong polarity. After work on the system, do check correct polarity of the battery and the regulator. Wrong polarity creates short circuits and will destroy the regulator, the ignition coil and the advance unit. As a rule, wiring will always be colour to colour. Instances, where colour jumps between wires are expressly mentioned in our instructions. |

|

# |

When you handle the new rotor, take care not to damage its magnets. Refrain from direct blows to the circumference of the rotor. When transporting never put the rotor over the stator. Observe our information relative to transport of the material. |

|

# |

Do not use spark plug sockets with a resistance of more than 5kOhm. Better use 1 or 2kOhm ones. Bear in mind that spark plug sockets do age and thereby increase their internal resistance. Should an engine start up only when cold, a defective spark plug socket and/or spark plug is very probably the cause. In case of problems check high tension cables too. Never use carbon fibre HT-cables, never use so called "hot wires" which promise to increase spark. |

|

# |

It is a good idea to cover the rotor in a thin layer of oil to reduce the risk of corrosion. |

|

# |

Never use a claw puller or a hammer to disengage the rotor. Its magnets might become loose in the event. We offer a special puller for disengaging the new rotor again (see assembly instruction)! |

|

# |

Should the motorcycle not be in use for some longer period, please disconnect the battery (so existing) to prevent current bleeding through the diodes of the regulator. Though, even a disconnected battery will empty itself after a while. |

|

# |

Please do observe these remarks, but at the same

time, don't be afraid of the installation process. Remember, that before you, thousands of

other customers have successfully installed the system. Enjoy driving your bike with its new electric heart! |