Powerdynamo brings new ignition & light

to your vintage motorcycle

|

|

Powerdynamo brings new ignition & light |

|

||||

| correct position between sensor and trigger nose is important for operation of external sensor triggered systems | |

|

|

|

click

picture to enlarge  |

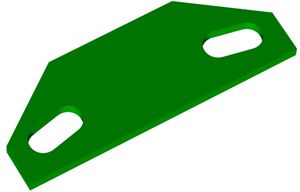

As a result of all sorts of things (notable such as

crankshaft modifications) it may happen that the rotor sits higher or

lower than conceived. In the case of external trigger systems it may

mean loss of spark. Make sure that sensor (the metal core in its middle) and trigger plate on rotor circumference are level. Here in the picture to the left it would mean that you still might get spark, but at very high starting revs. More extreme situations as sketched below ("problem") will produce only 1 spark at start and than totally suppress sparks.  If the rotor sits too high, you may push the sensor up to the needed level by a spacer plate (we offer 2mm thick plates under part 700030000). A rotor sitting too low needs to be replaced, as it would destroy the coils under it. |

|

|

|

|

Also very important for operation of such systems is correct gap. 0.4 is the standard. If gap is wider, starting will be more problematic, right up to impossible if you have values over 0.6-0.7mm |

|

|

|

|

should the gap between sensor and trigger sign have been

too small, leading to friction between the parts (you can see the

effect often on polishing traces at the rotorīs trigger sign or in more

extreme cases deep scratches there as shown here) than the sensor may have

been internally damaged even if its electrical

resistance is correct. Inside the sensor is a heat sensitive neodym magnet that looses magnetism if heated above a certain temperature (often reached by friction). The result is bad starting or outright ignition failure. The sensor has to be replaced. |

|

|

|

|

Should the sensor (getting loose) have interfered with the trigger plate than you have a destroyed sensor. Picture left shows some extreme case. But there are cases where you see nothing much, but still, the plastic mould may have been dislocated a bit and the very thin wire inside broke. Electrical resistance than is indefinite. Such events also manifest on the trigger plate, damaging the trigger plateīs edge. Should you find such damage, imperatively take the flywheel off and inspect its magnets and the stator coil. Very often the shock of impact between sensor and rotor produces damage there. |

| back | |