Very often customers when

experiencing ignition problems with Powerdynamo material installed suspect

the regulator as the culprit.

The regulator however has nothing to do with ignition at all.

Find below some information on what material might matter on instances of

ignition problems: |

|

|

On a PD stator internal pickup design you have 3 sorts of

coils. For how to electrically check those coils see Info

here

- a larger black coil which is responsible for generating the (rather

high 360-500V) voltage to load the CDI. This coil has some extremely

fine wire which can easily be damaged by physical impact on it.

- 2 smaller black coils either left or right of the larger black one

(depending on working sense of stator).

Those are responsible for triggering ignition (giving the pulse). They

also are sensible to mechanical impact, including force that changes

the angle between the 2. Sometimes a wire

is jammed under those coils shortcircuiting them and leading to

ignition failure.

- the copper coloured coils with some thicker wire are for generating

lighting voltage and have nothing to do with ignition. On special

stator for ignition only they

are even missing.

|

|

|

|

On a PD stator external pickup design (those systems which

have a sensor) you have 2

sorts of coils. For how to electrically check those coils see Info

here

- a larger black coil which is responsible for generating the (rather

high 360-500V) voltage to load the CDI. This coil has some extremely

fine wire which can easily be damaged by physical impact on it.

Some special stator have 2 such large coils.

- the copper coloured coils with some thicker wire are for generating

lighting voltage and have nothing to do with ignition.

|

|

|

|

- the sensor (pickup) is sensitive to mechanical impact also.

In most cases where it has been hit by the trigger nose of the rotor

or where pulling force had been exercised on its short yellow cable it

gets defective as internally it has some extremely fine wire which

than breaks. Only in rare

and severe cases you see the destruction. In most cases you see

next to nothing at best, under the magnifying glass, some small gap

between metal base and plastic cover. But you may always check its

electrical resistance which should read ca. 200 ohms (In case of

damage you mostly get indefinite readings)

|

|

|

|

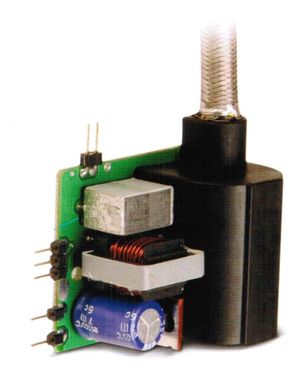

- most of our ignition coils are CDI units which contain not only

the normal transformer coils, but the complete condenser discharge (CDI)

unit.

Though there are plenty of electronics inside they really very rarely

fail - unless you mix up wires or (what already happened!) introduce

battery voltage.

|

|

|

|

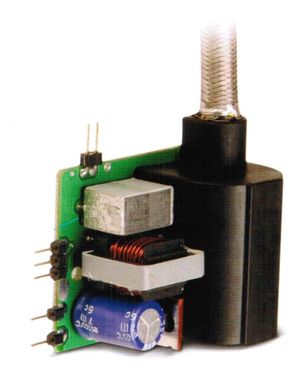

- a good many systems have advance units. They contain rather

sophisticated electronics, but are of some rather sturdy built and

failure is much less frequent than suspected by customers.

The unit will surely go defective when you mix up wires. The idea

that uneven engine run, lacking output at certain revs, difficult

starting or similar are caused by the unit is mostly unfounded. If

something is wrong with the unit than you mostly get no spark at all.

How to test (external pickup systems only) see

here

Failure indeed, notably on units for external pickup is rare! UNits for

internal pickup have also the CDI inside (and the respective ignition

coils than do not). Those units have a slightly higher risk of failure.

|

|

As you see, no role whatsoever for the regulator in ignition terms! The

regulator matters for lighting only.

Having said this, there is in some systems (those who have a cut-off

relay) one bridge between ignition and lighting circuit. This bridge is

broken when you disconnect the blue wire that runs to the relay

(recommended for troubleshooting)

Details see KB entry relay.

|