Powerdynamo brings new ignition & light

to your vintage motorcycle

|

|

Powerdynamo brings new ignition & light |

|

|||

|

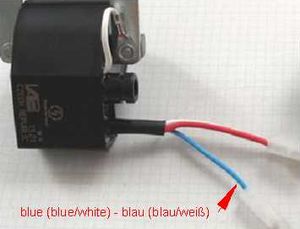

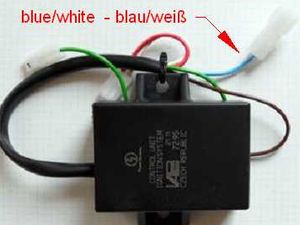

the famous blue wire ... |

|

|

|

|

|

All our CDI ignition coils and the advance control unit for

internal trigger systems s have a blue (sometimes also blue/white)

wire. This wire commonly called "kill wire" is for switching the

system off by shortcircuiting the internal capacitor. This function is needed as magneto based CDI systems would otherwise run until you run out of petrol (gas). We get many questions relative to this wire and its connecting. And there are potentially many ignition problems related to it. |

|

|

|

|

|

|

|

|

|

As explained, this wire, when connected to ground, shortcircuits the

capacitor inside the coil (or advance for internal trigger systems / only

this one! not the other advance units!).

|

|

|

|

|

|

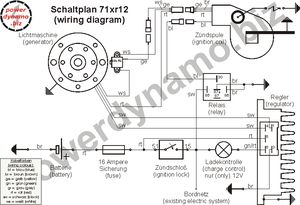

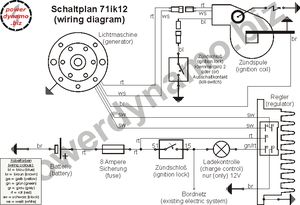

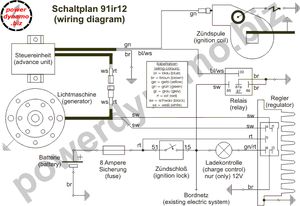

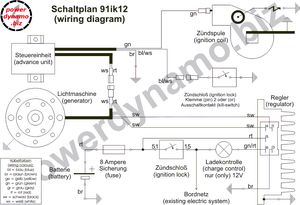

Follow typical wiring instructions for 2 stroke (only CDI coil) and

internal sensor advance controled (4 stroke) systems showing different

blue (kill) wire connection options Click diagrams to enlarge. |

|

|

|

|

| Wiring diagram for relay method 2 stroke | Wiring diagram for Killswitch method 2 stroke |

|

|

|

|

|

| Wiring diagram for relay method 4 stroke | Wiring diagram for Killswitch method 4 stroke |

|

|

|

|

|

| back to KB overview | |