Powerdynamo brings new ignition & light

to your vintage motorcycle

|

|

Powerdynamo brings new ignition & light |

|

||||

| It happens that a rotor slips on the shaft (thereby spoiling

timing). Customers tend to think that the reason is the (in most of our systems) missing woodruff key or arresting pin. The woodruf however has (except on cylindrical shafts) more a guiding, not so much a holding function. |

|

|

|

|

|

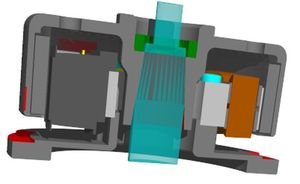

It has be said first that the rotor (in most applications where the crank shaft pin is tapered and not cylindrical) grips to the shaft because it also is tapered in the same taper (angle). If the taper is correct and both, shaft and rotor are not damaged (what old parts unfortunately often are) on the taper, the taper contact will provide enough grip to hold the rotor. You will notice when you just press the rotor by hand onto the shaft and than try to get it off by hand again. In most cases you will not manage and need a puller already there. click pictures to get enlarged views |

|

|

|

|

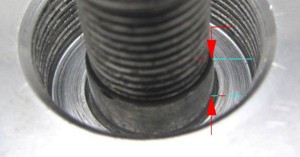

A frequent reason for slipping is that the shaft reaches a little, be

it 0.0xmm, into the screw opening of the rotor as shown - a little

amplified - in the picture here. |

|

|

|

|

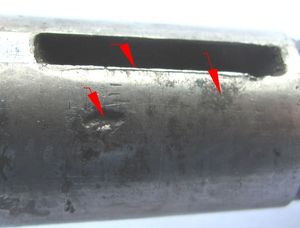

Also quite often are cases where the shaft is damaged, notably at the groove for the woodruff where it has developed small rises. The woodruff actually is not so much a holding, but a guiding device. See info here Rust also does not help a good grip. |

|

|

|

| Notably the 2kg rotor are in risk of slipping. We have

seen only few heavy stock rotor which did not show slipping damage. The

large mass works a lot when engine changes speed. It helps a lot to grind rotor and shaft together with valve-grinding paste. Put some paste on the shaft, place the rotor on and gently turn it on the shaft back and forth until the shaft has developed a nice grey area. Than clean off all remaining paste. Use of any glue, such as loctite is not recommended by us. |

|

|

|

|

|

A good thing is to add a curved spring washer (not a normal open spring washer please!).

|

|

| Never use glue (say loctite) to

help the grip of the rotor. You just get the opposite result as the

contact area between the 2 tapers gets spoiiled by the glue.

Same happens when you (to better enable later pulling) apply grease. Never apply grease to the shaft at the taper area! Also, wipe shaft und rotor taper clean and dry before you set the rotor. |

|

|

|

|

| Information on torques for fastening PD rotor see here | |

| back to KB | |