Powerdynamo brings new ignition & light

to your vintage motorcycle

|

|

Powerdynamo brings new ignition & light |

|

||||

|

|

||||||

HELP ! |

click pictures to enlarge them |

||

|---|---|---|---|

| I get only one spark on my internal sensor Powerdynamo and than nothing. What can I do ? | |||

|

|

|||

| This page assumes that you have already double checked wiring (ground!) and that you are aware of the focused nature of the high energy spark. | |||

|

|

|||

| In the majority of cases the reason for this failure is a damaged wire underneath the stator, shortcircuiting one of the small black coils. | |||

|

You can check that with an Ohm meter as long as the stator in question is

still mounted to the engine with the spark problem still prevailing. Do

not take off the stator for this check.

Measure resistance between the white and the brown wire from the stator. That should typically be above 70 Ohm. If you get only half that value, something like 35 Ohm, you have found a short circuited wire as the cause of your ignition problems. |

|||

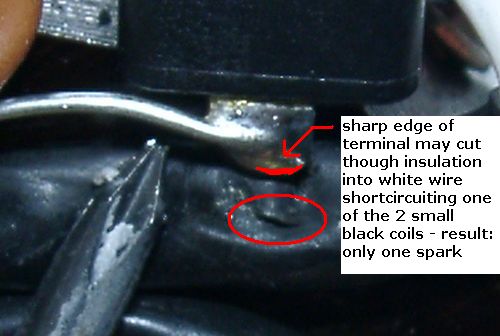

| Sometimes during assembly one black wire from the light coils that runs under the stator gets jammed! As a result it is pushed from center into the (insulated) white wire from the 2 pickup coils. This white wire in turn then presses against the soldered terminal at the base of the small black coils. The terminal has rather sharp edges and presses the wire through the insulation and into the white wire - shortcircuiting one of the 2 smaller black coils. | |||

|

|

|||

It

might well be that initially all is ok, but a while under the

influence of heat and vibration insulation will wear through and cause a failure

of the system. It

might well be that initially all is ok, but a while under the

influence of heat and vibration insulation will wear through and cause a failure

of the system.

|

|||

|

|

|||

|

The stator coil will not get damaged as such in the process,

but you will experience only one spark at start and then nothing. Well,

actually you get 6 sparks per revolution, but at start up with low output

(low start revs) those six will each bite into the power produced

and you will see nothing. With a stroboscopic light (and a white mark

on the rotor) you will see during kickstart or better when youn

electrically propell the engine (electric drill with rubber head) 6

reflecting markings pointing to 6 sparks per revolution.

Tricky, but easily resolved and preventable using a little more care during assembly. |

|||

|

|

|||

| If you do not find the above described scenario as the reason of your ignition failure, here are some more guidelines for further checking. | |||

| Take the rotor off (please use only a suitable

tubular puller M27x1.25, no claw puller or similar!) and inspect

both rotor and stator carefully. Watch out for alien material (bits of

metal between the magnets), broken or loose magnets (in that case you will

see plenty of damage anyway) and damaged stator coils. If you find things

like that, you have found the reason for the systems malfunctioning, but you will

still have to look for the reason of the damage.

Here is a list of things we have seen gone wrong:

|

|||

|

|

|||

| Check resistance between the red and the brown wire of the stator. You should get a reading of about 530 Ohms. The coil concerned is the larger black coil. | |||

|

|

|||

| If you get a value of 0 Ohm, take the stator coil off and check whether the red wire has been caught and shortcircuited between statorbase and adapter. |

|

If that happens, try to insulate the wire and make sure that it will not be

crushed any more between stator and base. Chances are high that the coil has been burned as a result of the short circuit. In that case, you have to replace the stator. |

|

|

|

|||

| If you get a value much lower than 530 Ohm (say 300 Ohm or so) but higher than 0 Ohm, the larger black coil has been burned and developed a partical shortcircuit. The reason for this is mostly to be found in a short circuited (crushed) red wire. |

|

If that happens you have to replace the stator. |

|

|

|

|||

| If you get an infinite reading, take the stator coil off and check whether the red wire has been cut somewhere or whether you notice any physical damage to the larger black coil. Such damage often happens when unsuitable puller tools is used which protrude through the rotor openings into the coils. | If that happens you have to replace the stator. | ||

|

|

|||

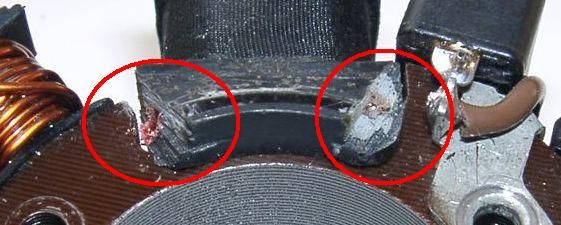

A

really good example of damage due to negligence during assembly. A

really good example of damage due to negligence during assembly.

|

|||

|

|

|||

| Other possible causes for a malfuntion. | |||

| Though it should never happen, and we take great care to prevent that happening, it is not impossible that we have delivered you the wrong material. Wrong notably in the sense of the wrong directione of rotation. All systems are protected against starting the engine turning the wrong way (in that case your motorcycle will drive backwards!). Here is how to tell what material is for which direction. | |||

|

left turning (anti-clockwise) |

right turning (clockwise) |

||

|

|

|

||

|

Left or right are defined by looking at the face of the installed rotor |

|||

|

|

|

||

|

|

|||

| A further theoretical problem might be the wrong rotor. "Theoretical" as it should not happen that we'll deliver that, but between heaven and earth anything is possible, so to be on the safe side, we'll mention it here. | |||

|

There has to be a non-magnet amongst the 12 visible magnets. You can tell by touching them individually with a iron object, such as a screw driver (make sure it is ferrous material).

The position of that non magnet is shown here. |

||

|

|

|||

| back to trouble shooting page | |||