|

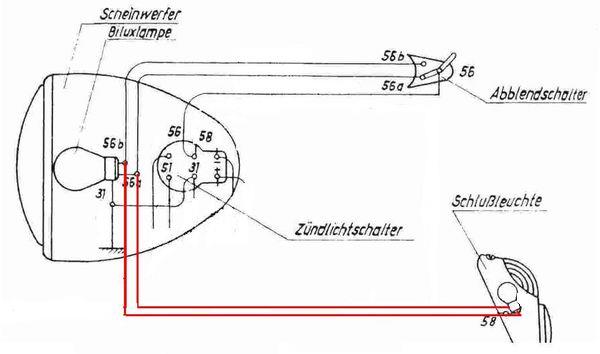

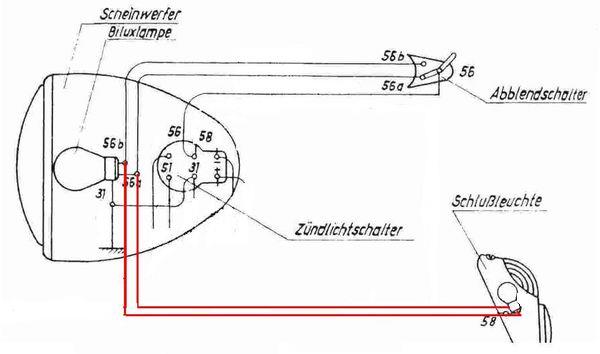

wiring suggestion for 788 systems (6v/18w without

regulator) to prevent trail light blowing when changing between low and high

beam

|

|

|

If headlight and taillight bulbs are wired normally in parallel, it happens

that during switchover from low to high beam or reverse, there is briefly no

current on the headlight bulb and as a result voltage may rise at the

taillight bulb, blowing it. This is not only so on our systems 788, but also

on stock systems. Some manufacturers at the time combatted this with either

including a trottle coil or by using safety wiring of the tail bulb.

|

|

|

we here describe this safety wiring and recommend that you use this with

our 788 systems if the bike has a dipswitch and is therefore liable to

taillight blows

|

|

|

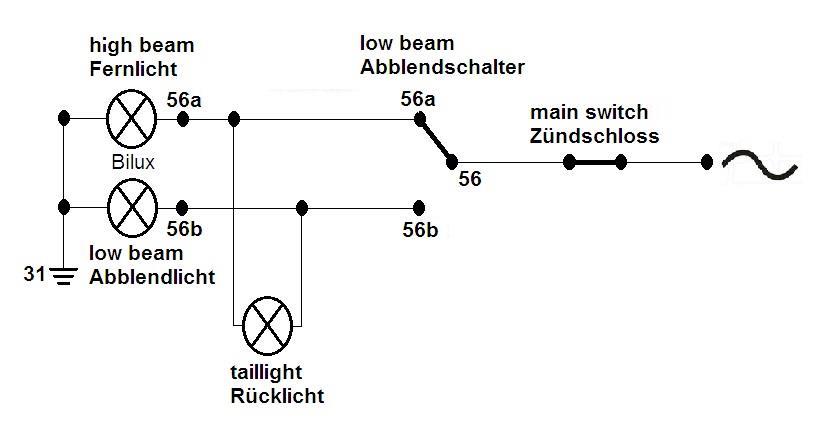

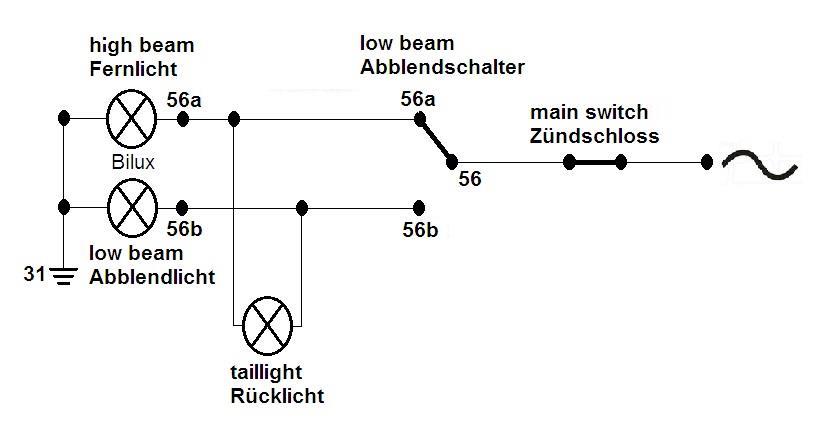

What you need to do (it might be that your bike has already such wiring, so

check) is to disconnect the grounding of the taillight lamp and install some

additional wire to the bulb, replacing the former ground connection. You now

have 2 wires from the taillight bulb.

Connect them, one each, to the high and low beam contacts of the headlight

bulb as shown above (and also shown in basic wiring diagram below).

With this wiring when the dipswitch is between the states and does not

supply the headlight bulb (which would be the moment of risk for the

taillight bulb) there is also no voltage at the taillight bulb. Note

hoiwever that if the headlight bulb blows, your taillight will not shine any

more either.

|

|

|

|